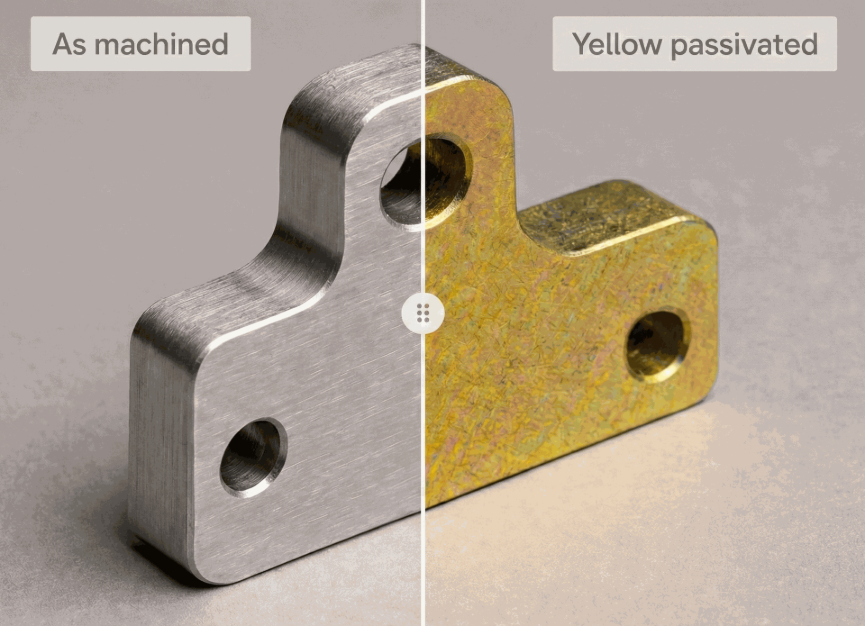

A chemical conversion coating, known as yellow passivation, is applied to mild steel that has been plated with zinc to enhance corrosion resistance and extend service life.

The process creates a thin layer of yellow chromate on top of the zinc surface, and that acts as a barrier that prevents rust and oxidation.

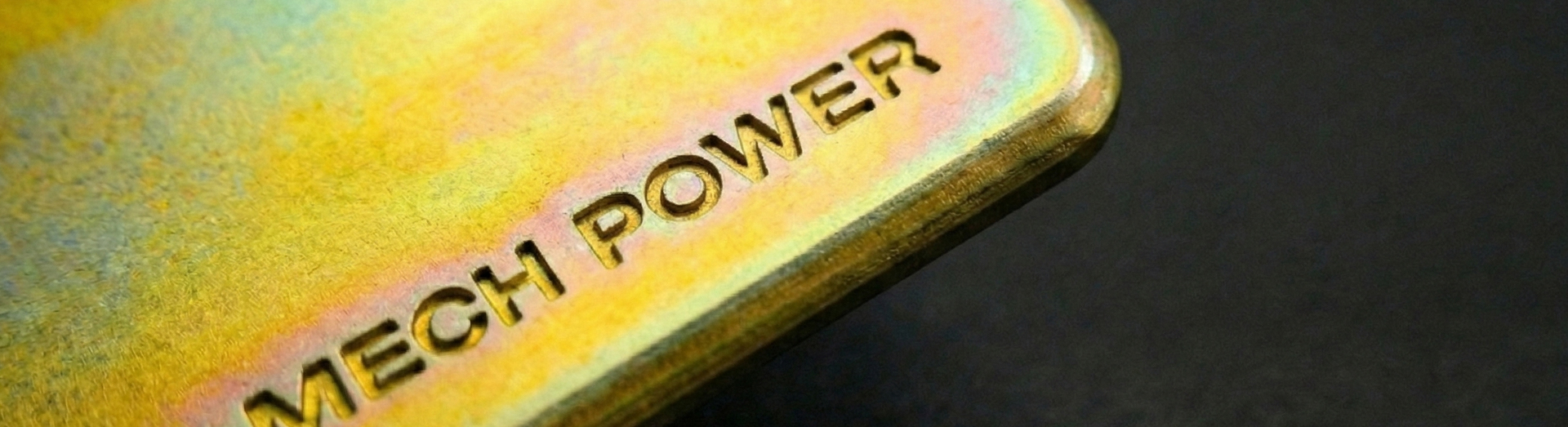

The finish naturally provides an iridescent yellow to golden tint, which may be more prominent in UV or angled light.

Yellow Passivation Specification

Surface preparation | Colors | Applicable materials | Thickness | Visual appearance |

Zinc plated (after machining) | Yellow to golden chromate tint with subtle iridescence | Mild steel only | Negligible, almost no dimensional change | Zinc-plated surface with a uniform yellow chromate layer; base texture remains visible |

Yellow Passivation Specification

Surface Preparation: Zinc-plated surface (after machining)

Color: Yellow to golden chromate tint with subtle iridescence

Applicable Materials: Mild steel only (zinc plated)

Thickness: Negligible, almost no dimensional change

Visual Appearance: Zinc-plated surface with a uniform yellow chromate layer; base texture remains visible

Sample of Yellow Passivated Mild Steel Part

Design Considerations for Yellow Passivation

- Part dimensions and tolerances are maintained because yellow passivation creates a thin layer of chemical conversion, ensuring precise measurements.

- This finish applies only to mild steel parts with zinc plating.

- This method cannot be used to yellow passivate aluminum or stainless steel.

- Since this finish is utilitarian rather than decorative, surface texture and machining marks are still discernible.

- The coating offers a moderate level of corrosion resistance, making it appropriate for controlled indoor environments.

- Without extra protection, it is not advised for outdoor, marine, or extremely corrosive environments.

How Yellow Passivation Works at Mech Power

To increase corrosion resistance and ensure constant surface protection, Mech Power applies yellow passivation exclusively to mild steel parts after zinc plating.

A consistent yellow chromate color in the final finish indicates that the zinc layer has been properly passivated.

Process We Follow

To get rid of pollutants, oil, and grime, mild steel parts are cleaned and degreased.

- Zinc electroplating is used to generate a base layer that prevents corrosion.

- Parts with zinc plating are properly cleaned.

- The conversion coating is created by dipping the parts in a yellow chromate passivation bath.

- Parts are taken out after the yellow film appears.

- A final rinse and drying stabilize the coating.

Read more about Yellow Passivation

FAQS

Frequently Asked Questions

A chemical conversion finish called yellow chromate passivation is applied to mild steel that has been plated with zinc to enhance its corrosion resistance.

No. Paint or powder coating is not the same as yellow passivation. On zinc, it is a thin layer of chemical conversion.

Yellow chromate passivation is only available at Mech Power for mild steel parts that have undergone zinc plating.

No. Dimensions and tolerances are unaffected by yellow passivation, which has very little thickness.

Variations in color, ranging from slightly yellow to iridescent, are typical and are determined by process conditions rather than performance.