Upload CAD file/Submit Inquiry

Upload your design or submit inquiry details.

Manufacturing Made Flexible: Custom Metal & Plastic Parts, Produced On Demand!

WHAT IS

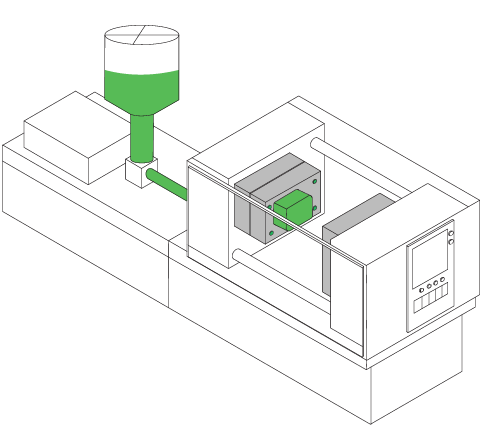

Delve into Mech Power's advanced Injection Molding services, where precision meets innovation in engineering-grade plastic parts manufacturing. Our state-of-the-art facilities boast fully automatic microprocessor-controlled machines, ensuring impeccable quality and efficiency.

MATERIALS

Explore our range of versatile Injection Molding materials:

Strong, tough, and heat-resistant, ideal for engineering prototypes and automotive parts.

Exceptional impact resistance and clarity, commonly used in safety equipment and electronic components.

Blends strength and toughness for high-performance applications.

Versatile with high strength and abrasion resistance, suitable for gears and bearings.

Lightweight with excellent chemical resistance, ideal for packaging and automotive parts.

Exceptional heat resistance and flame retardancy, used in aerospace and electrical components.

High-strength with excellent mechanical properties, perfect for precision engineering.

SERVICES

Our customization offerings in injection molding allow products to be tailored to your specific preferences or requirements, enhancing both personalization and functionality for your plastic parts and prototypes.

Mech Power’s UV printing service enhances your products by offering high-quality, durable prints on various surfaces.

Whether it's logos, features, product information, or custom designs, our UV printing services ensure vibrant colors and sharp details that withstand wear and tear, enhancing the appearance and branding of your custom enclosures and plastic parts.

Get started by selecting your preferred manufacturing process to get a quick, accurate project estimate.

FROM QUOTE TO DELIVERY

Upload your design or submit inquiry details.

Configure part specifications and get an immediate quote.

Our engineers will review the design for manufacturability.

We ensure parts are made to meet our high-quality standards.

Confirm payment, and we’ll schedule delivery at your convenience.

APPLICATION

Injection Molding’s

Versatility

Our versatile solutions and commitment to precision ensure we meet your industry-specific needs, delivering excellence in injection molding, custom enclosures, and plastic parts.

UNMATCHED SOLUTIONS

Processing Your Request...

Your Request Has Been Submitted!

Thank you for your interest in our Injection Molding service! Our team will get back to you shortly to discuss your requirements further.

Continue to websiteCONTACT US

Share your contact details, and our dedicated team will be in touch shortly to discuss your requirements further.

FAQS

Lead times for injection molding depend on factors such as mold design complexity, material selection, and part quantity. Typically, it can take 02 - 08 weeks for mold creation, followed by production time, but we work to meet your specific deadlines.

We implement strict quality control measures, including mold inspections, in-process testing, and final product inspection. Our advanced technology and experienced engineers ensure that each part meets your specifications and industry standards.

Costs are influenced by factors like part complexity, material choice, mold design, and production volume. To reduce costs, we suggest optimizing your design for manufacturability, selecting cost-effective materials, and increasing production volumes.

The minimum order quantity depends on the mold and production complexity. For custom orders, we can discuss specific requirements based on your project needs.