Upload CAD file/Submit Inquiry

Upload your design or submit inquiry details.

Manufacturing Made Flexible: Custom Metal & Plastic Parts, Produced On Demand!

WHAT IS

At Mech Power, we bridge the gap between your Sheet Metal concepts and reality. Our tailored design solutions seamlessly blend functionality and aesthetics, making your visions tangible.

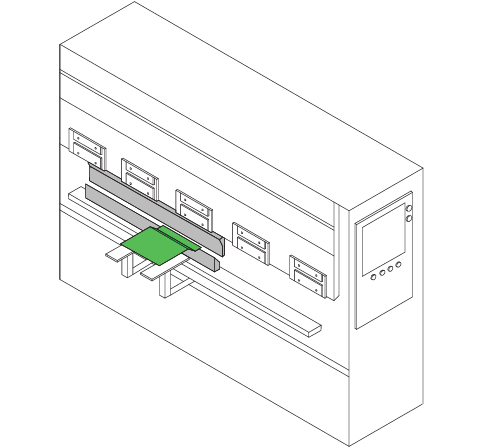

Sheet Metal Fabrication Capabilities

Explore our diverse Sheet Metal Fabrication capabilities, from high-speed CNC Punching to precise Laser Welding for custom enclosures, panels, and precision parts, crafted with unmatched accuracy and finish.

Clamping Force: 53 KN, ensuring secure fastener integration.

Stroke Length: 200mm for precision in inserting fasteners.

Throat Depth: 450mm for versatile application and flexibility.

Laser Type: Fiber for refined welding.

Laser Power: 1500W, delivering precise and efficient welding capabilities.

Laser Source: Raycus for quality and reliability.

Rating: 15 KVA

Standard Throat Depth: 300mm

Max Electrode Stroke:

70mm

Welding Range: MS (3mm), SS (2.8mm), Brass (1.5mm)

MATERIALS

Explore our range of versatile metal materials:

Known for its strength and durability, mild steel is widely used in construction, automotive, and machinery industries.

Resistant to corrosion and staining, stainless steel is favored for its durability and hygienic properties, making it suitable for food processing, medical, and marine applications.

Lightweight and corrosion-resistant, aluminum is commonly used in aerospace, automotive, and electronic applications.

A durable, corrosion-resistant material with a zinc coating, offering strength, stability, and a polished finish for industrial and outdoor projects.

SERVICES

Customization offerings allow products to be tailored to specific customer preferences or requirements, enhancing personalization and functionality in sheet metal fabrication and other custom projects.

Mech Power’s UV printing service enhances your products by providing high-quality, durable prints on various surfaces.

Whether it's logos, features, product information, or custom designs, our UV printing delivers vibrant colors and sharp details that withstand wear and tear, elevating the appearance and branding of your sheet metal enclosures and custom projects.

Get started by selecting your preferred manufacturing process to get a quick, accurate project estimate.

FROM QUOTE TO DELIVERY

Upload your design or submit inquiry details.

Configure part specifications and get an immediate quote.

Our engineers will review the design for manufacturability.

We ensure parts are made to meet our high-quality standards.

Confirm payment, and we’ll schedule delivery at your convenience.

APPLICATION

Sheet Metal Fabrication’s

Versatility

UNMATCHED SOLUTIONS

Processing Your Request...

Your Request Has Been Submitted!

Thank you for your interest in our Sheet Metal Fabrication service! Our team will get back to you shortly to discuss your requirements further.

Continue to websiteWHAT'S NEW

Sheet Metal Fabrication

5 Things to Check Before Ordering Custom Sheet Metal Parts

16 February, 2026

Sheet Metal Fabrication and 3D Printing

Case Study: Hybrid Metal and 3D Printed Enclosure for a Medical Device

16 February, 2026

Sheet Metal Fabrication and 3D Printing

One Manufacturing Partner for Plastic Parts, Metal Parts and Enclosures

06 February, 2026

FAQS

The typical turnaround time for sheet metal fabrication varies depending on the metal’s thickness, design complexity and the number of parts you require.

Yes, we specialize in prototyping to help you validate designs and functionality before moving to full-scale production.

Yes, our team offers design consultation to optimize your parts for manufacturing and ensure cost-efficiency.

The cost of sheet metal fabrication is influenced by material type, part complexity, thickness, quantity, and finishing requirements. Optimizing designs and material selection can help minimize costs.