Upload CAD file/Submit Inquiry

Upload your design or submit inquiry details.

Manufacturing Made Flexible: Custom Metal & Plastic Parts, Produced On Demand!

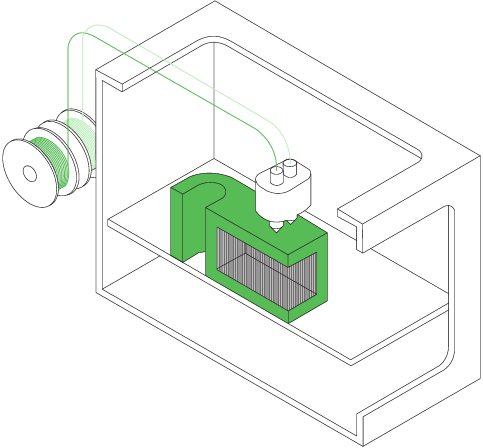

WHAT IS

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication, is an advanced 3D printing technique. It produces functional parts and prototypes by precisely melting and depositing material layer by layer, resulting in accurate and durable three-dimensional structures.

MATERIALS

Explore our range of versatile FDM 3D printing materials:

Derived from renewable sources such as cornstarch or sugarcane, PLA is a fully biodegradable thermoplastic. Its versatility and eco-friendliness make it an excellent choice for a wide range of applications, from prototypes to functional parts.

Known for its strength, toughness, and heat resistance, ABS filament is a preferred option for engineering prototypes and functional parts. Its impact strength makes it a reliable choice for various applications.

With outstanding chemical and thermal resistance, PETG is a high-strength, clear thermoplastic material. It is particularly suitable for projects that demand both durability and clarity.

ASA offers superior UV stability, making it an ideal choice for projects that will be exposed to sunlight. Its post-processing capabilities, chemical resistance, and durability further enhance its suitability for various applications.

TPU is a flexible filament that mimics rubber-like elasticity. Its high elasticity and resilience make it perfect for projects requiring impact resistance and dynamic properties.

Combining the flexibility of rubber with the processing ease of plastic, TPE offers a versatile solution for projects that demand a balance between flexibility and structural integrity.

SERVICES

Customization offerings allow products to be tailored to specific customer preferences or requirements, enhancing personalization and functionality.

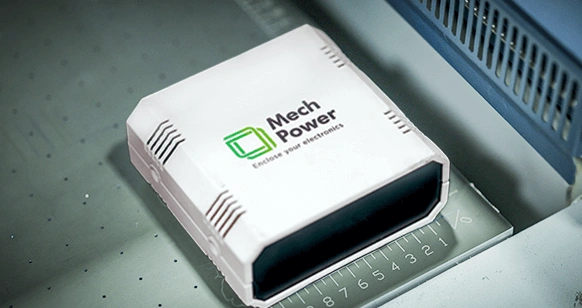

Mech Power’s UV printing service enhances your products by offering high-quality, durable prints on various surfaces.

Whether it’s logos, features, product information, or custom designs, our UV printing ensures vibrant colors and sharp details that withstand wear and tear, elevating the overall appearance and branding of your enclosures.

Get started by selecting your preferred manufacturing process to get a quick, accurate project estimate.

FROM QUOTE TO DELIVERY

Upload your design or submit inquiry details.

Get an quote.

Our engineers will review the design for manufacturability.

We ensure parts are made to meet our high-quality standards.

Confirm payment, and we’ll schedule delivery at your convenience.

APPLICATION

FDM creates prototypes mirroring functionality.

From electronics to robotics, FDM crafts enclosures for diverse industries.

FDM crafts jigs, fixtures for streamlined manufacturing.

FDM speeds design iteration and innovation cycles.

GUIDE

OUR WORK

UNMATCHED SOLUTIONS

Fast Turnaround

No Minimum Order Quantity

Material Variety

Processing Your Request...

Your Request Has Been Submitted!

Thank you for your interest in our Fused Deposition Modeling service! Our team will get back to you shortly to discuss your requirements further.

Continue to websiteCONTACT US

Share your contact details, and our dedicated team will be in touch shortly to discuss your requirements further.

WHAT'S NEW

3D Printing

How 3D Printing is Changing Custom Enclosures in the Automotive Industry

25 February, 2026

3D Printing

FDM vs Resin 3D Printing: Which is Best for Your Prototypes in 2026?

20 January, 2026

3D Printing

Material Spotlight: Choosing The Right Resin For Your 3D Printed Parts And Enclosures

15 December, 2025

The durability of FDM parts depends on the material used and the design of the part. Materials like ABS and Nylon offer excellent strength and impact resistance, making them suitable for functional and mechanical applications.

Yes, FDM technology can produce complex geometries, but it may require support structures for overhangs and intricate details, which can be removed post-printing.

FDM is cost-effective, reliable, and offers a quick turnaround for prototypes and functional parts. It is also versatile in terms of material selection and scalability.

The cost of FDM printing depends on factors like material type, part size, infill density, and post-processing requirements. Choosing efficient designs and materials can help reduce costs.