SERVICES

3D Printing Service

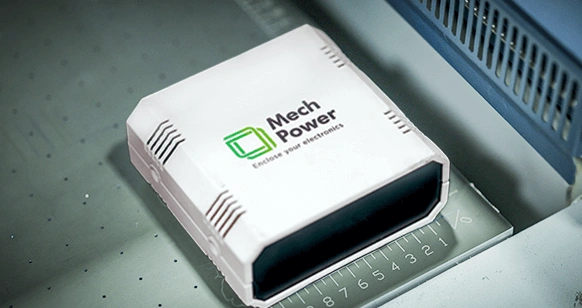

Explore Mech Power's cutting-edge 3D printing services, where innovation meets precision engineering. With expertise in Fused Deposition Modeling (FDM) and Resin 3D Printing, we deliver high-quality prototypes and production parts across a wide range of materials. From functional enclosures to intricate custom parts, every build is built with accuracy, consistency, and finish in mind. With Mech Power, you can 3D print online and receive expertly produced parts with uncompromising quality and speed.

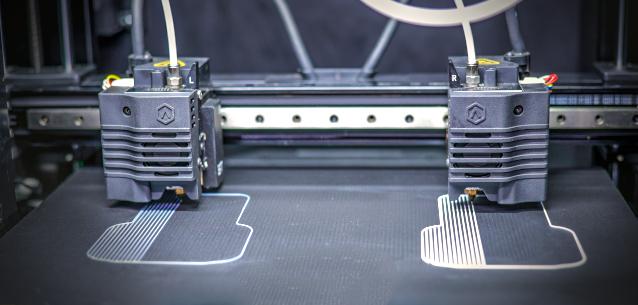

Fused Deposition Modeling (FDM)

Explore the groundbreaking Fused Deposition Modeling (FDM) technology – a game-changer in cost-effective prototype manufacturing. With precise layer-by-layer deposition, FDM empowers you to create intricate designs and functional prototypes with unmatched efficiency.

Resin 3D Printing

Embark on a journey into the realm of Resin 3D Printing, where the interplay of light meticulously shapes intricate designs, layer by layer. This cutting-edge process lays the foundation for pioneering innovation, redefining the boundaries of what's possible.

Get Instant Pricing for Your Parts

Get started by selecting your preferred manufacturing process to get a quick, accurate project estimate.

SERVICES

Customization Offerings

Personalize your enclosures and parts with Mech Power’s online 3D printing services, where customization meets functionality. Our tailored solutions ensure every 3D printing enclosure is built to match your exact preferences and performance needs.

UV Printing

Mech Power UV printing service enhances your products by offering high-quality, durable prints on various surfaces.

Whether it’s logos, product features, information, or custom designs, our UV printing delivers vibrant colors and sharp details that withstand wear and tear—enhancing the appearance and branding of your 3D printing enclosures through our online 3D printing services.

METHODS

Unsure about the right 3D printing method?

Here's a comparison guide to help you choose the right 3D printing technology.

UNMATCHED SOLUTIONS

Why Choose Mech Power for 3D Printing Service?

Fast Turnaround

No Minimum Order Quantity

Material Variety

WHAT'S NEW

Our Blogs

3D Printing

How 3D Printing is Changing Custom Enclosures in the Automotive Industry

25 February, 2026

3D Printing

FDM vs Resin 3D Printing: Which is Best for Your Prototypes in 2026?

20 January, 2026

3D Printing

Material Spotlight: Choosing The Right Resin For Your 3D Printed Parts And Enclosures

15 December, 2025

FAQS

Frequently Asked Questions

We accept .stl, .step, and .stp files for instant quotes.

FDM is ideal for larger, functional parts, while Resin 3D Printing offers faster, high-resolution results for intricate designs.

The cost of your 3D printed parts is influenced by factors like part volume, design complexity, material selection, the 3D printing technology used, and any required post-processing. To check the cost of your 3D printed part, visit our Instant Quote page & upload your file.

We offer a variety of materials, including PLA, ABS, Nylon, PETG, and flexible materials, each suitable for different applications. Our team can guide you in selecting the right material based on your project requirements.