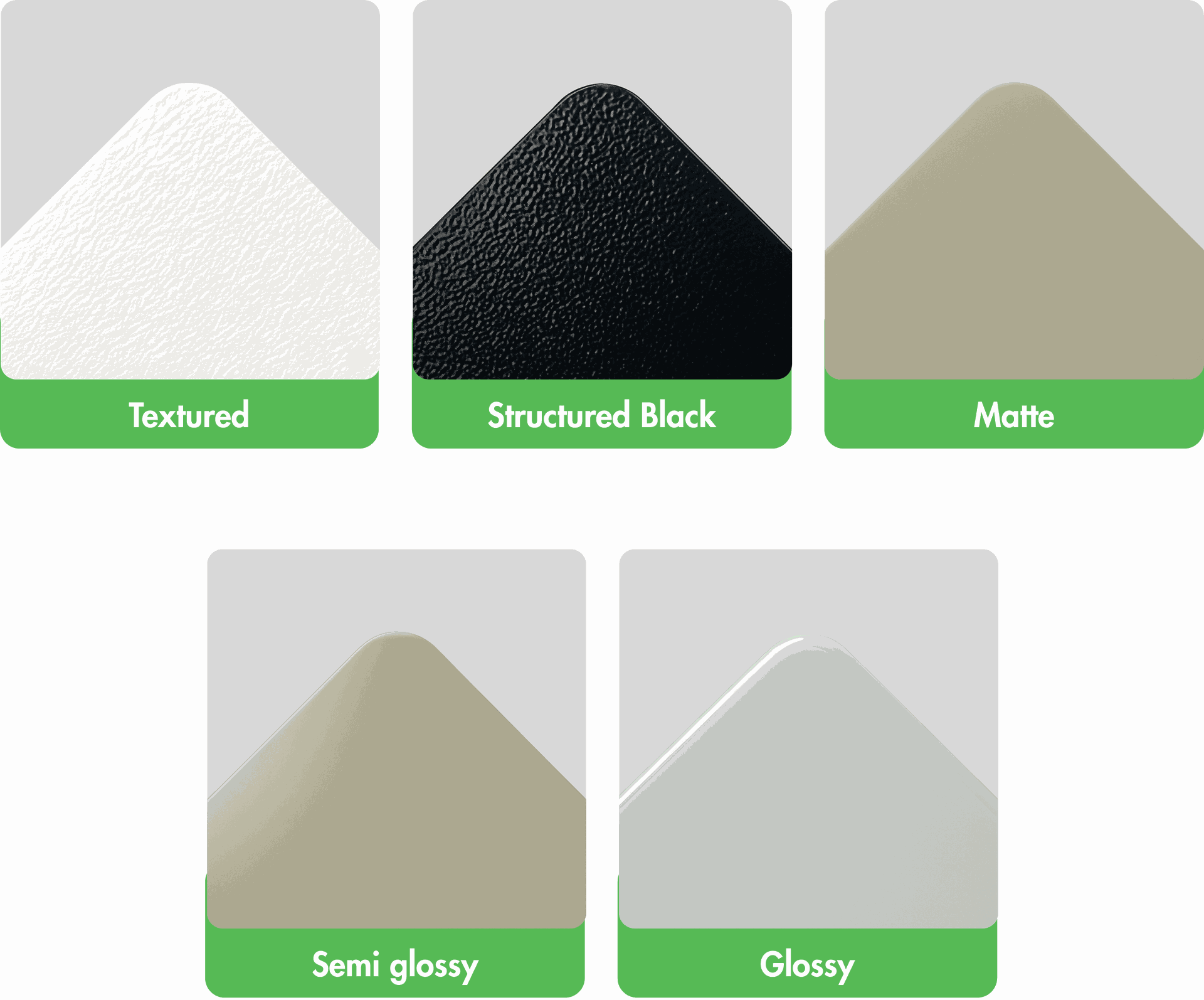

We offer durable powder-coating finishes that enhance the strength, corrosion resistance, and overall appearance of your metal custom parts and enclosures. Our powder coating supports all metal materials and is available in structured, textured, glossy, semi-glossy, and matte finishes, making it ideal for both industrial applications and electronics-ready builds.

Power Coating – Specification

Surface preparation | Colors* | Glossiness | Thickness | Visual appearance |

As machined (Ra 3.2μm / Ra 126μin) | Structured: Black RAL 9005, RAL 9003, RAL 7032 | Textured / Structured (Industry standard: coarse texture — GU not defined) | 80μm to 150μm | Heavily textured, rugged finish applied after machining |

As machined (Ra 3.2μm / Ra 126μin) | Textured: Grey RAL 7035, RAL 9003, RAL 7032 | Fine texture (Industry standard: low gloss due to texture) | 70μm to 150μm | Slightly grainy texture offering better scratch resistance |

As machined (Ra 3.2μm / Ra 126μin) | Glossy: Grey RAL 7035, RAL 9003, Black | Glossy (Approx. ≥ 70 GU – global standard) | 60μm to 120μm | Smooth, high-shine surface applied after machining |

As machined (Ra 3.2μm / Ra 126μin) | Matte: RAL 7032, Grey RAL 7035 | Matte (Approx. ≤ 30 GU – global standard) | 60μm to 120μm | Low-shine, uniform finish applied after machining |

As machined (Ra 3.2μm / Ra 126μin) | Semi-Glossy: RAL 9003, RAL 7032, Black, Grey RAL 7035 | Semi-gloss (Approx. 40–70 GU – global standard) | 60μm to 120μm | Smooth finish with moderate shine applied after machining |

Gloss Options for Powder Coating

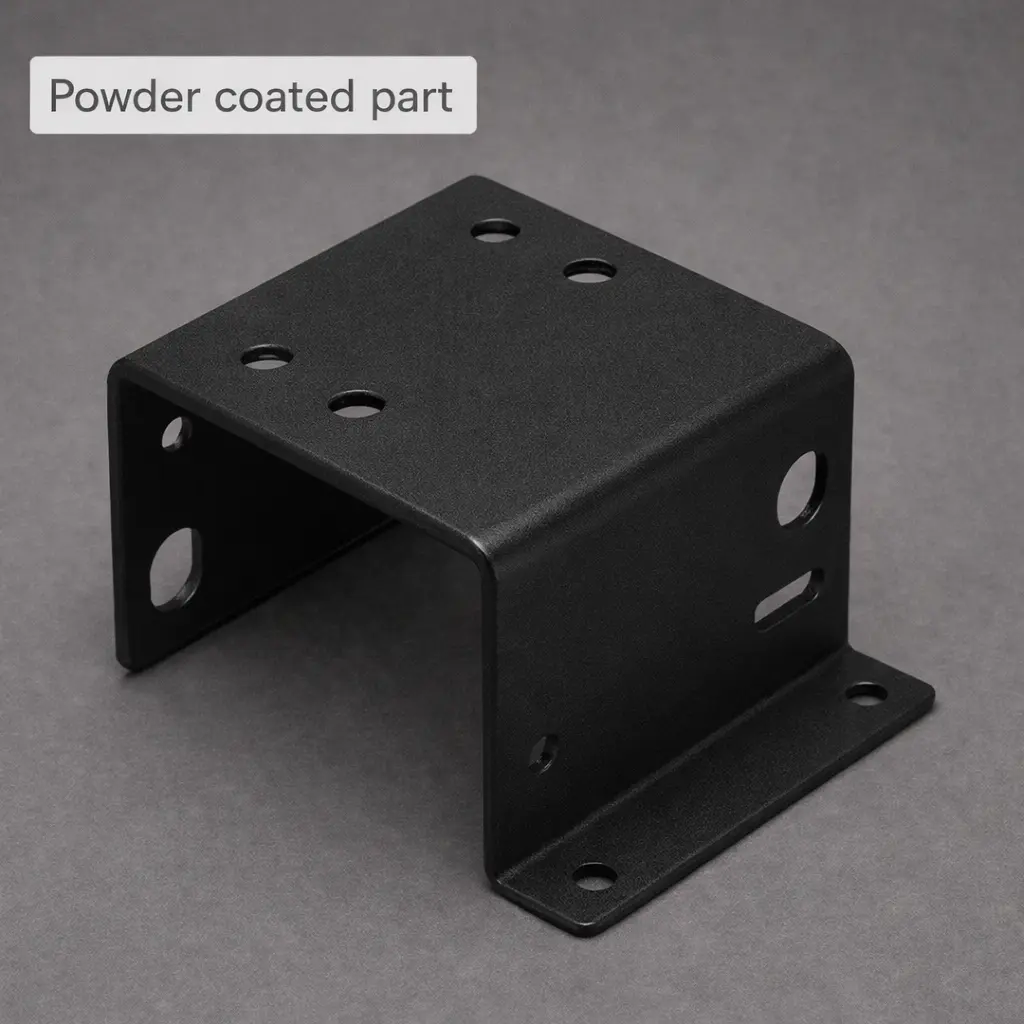

Powder Coated Part

Design Considerations for Powder Coating

Hanging & jigging marks

Powder coating requires parts to be hung on a jig or rack for spraying and curing.

This may leave a small uncoated area where the part was held.

If there are locations where jig marks are unacceptable, please indicate them in your drawing so we can plan the holding points accordingly.

Masking

If certain areas of your enclosure or part must remain uncoated, please mark them clearly in your design file.

During powder coating, all threaded holes, reamed holes, grounding points, and other critical-to-function surfaces are masked or plugged by default.

Additional masking can be done as per your request.

Tolerances

Dimensional tolerances are achieved before powder coating.

Since coating adds thickness, we recommend discussing any tight-fit areas, sliding assemblies, or PCB seating regions that may require masking to ensure a proper fit.

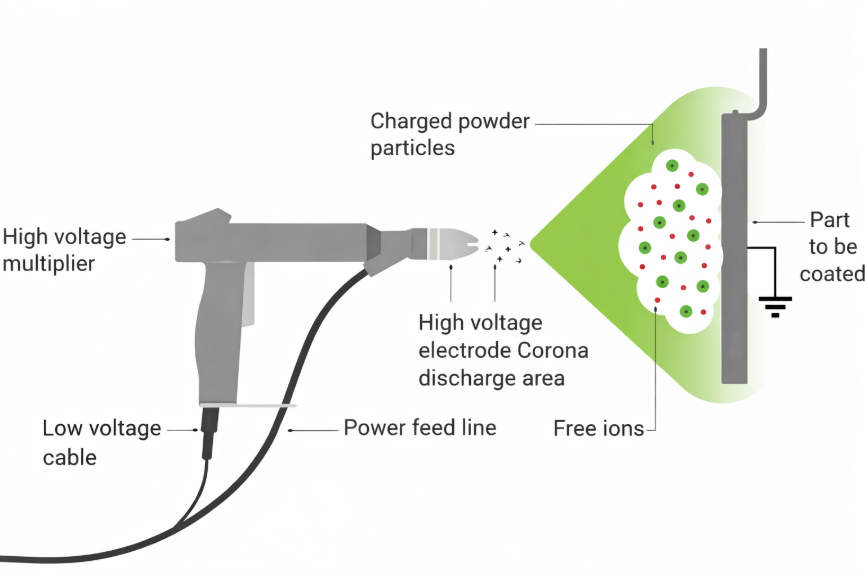

Powder Coating Process

Powder coating offers a strong, long-lasting, and wear-resistant surface for both metal parts and enclosures, and precision components. It provides long-term protection from corrosion, scratches, and weather exposure, making it excellent for industrial and electrical applications.

How we apply powder coating at Mech Power

- Clean the parts properly to get rid of oils, dust, and fabrication residues.

- Pretreatment of parts, depending on the material, can improve adhesion and corrosion resistance.

- After pretreatment, the parts are cleaned and oven-dried.

- To ensure operation, critical places, including threaded holes, grounding points, and tight-fit zones, are masked.

- The powder is then applied using an electrostatic spray cannon to ensure even coverage on all surfaces.

- Finally, the coated components are baked in an industrial oven until the powder melts and provides a hard, lasting surface.

FAQS

Frequently Asked Questions

We support powder coating on all metal parts and enclosures, including steel and aluminum.

It offers strong resistance to wear, corrosion, and daily handling, making it ideal for industrial use.

Yes. Threaded holes, grounding points, and tight-fit regions can be masked on request.

Structured, textured, glossy, semi-glossy, and matte, each available in selected RAL colors.

Yes, coating adds thickness. Tolerance-critical areas should be highlighted for masking.