Anodizing strengthens and improves your aluminum parts by depositing a controlled oxide coating on the surface.

This protective coating boosts corrosion resistance and durability, and delivers a clean, long-lasting appearance.

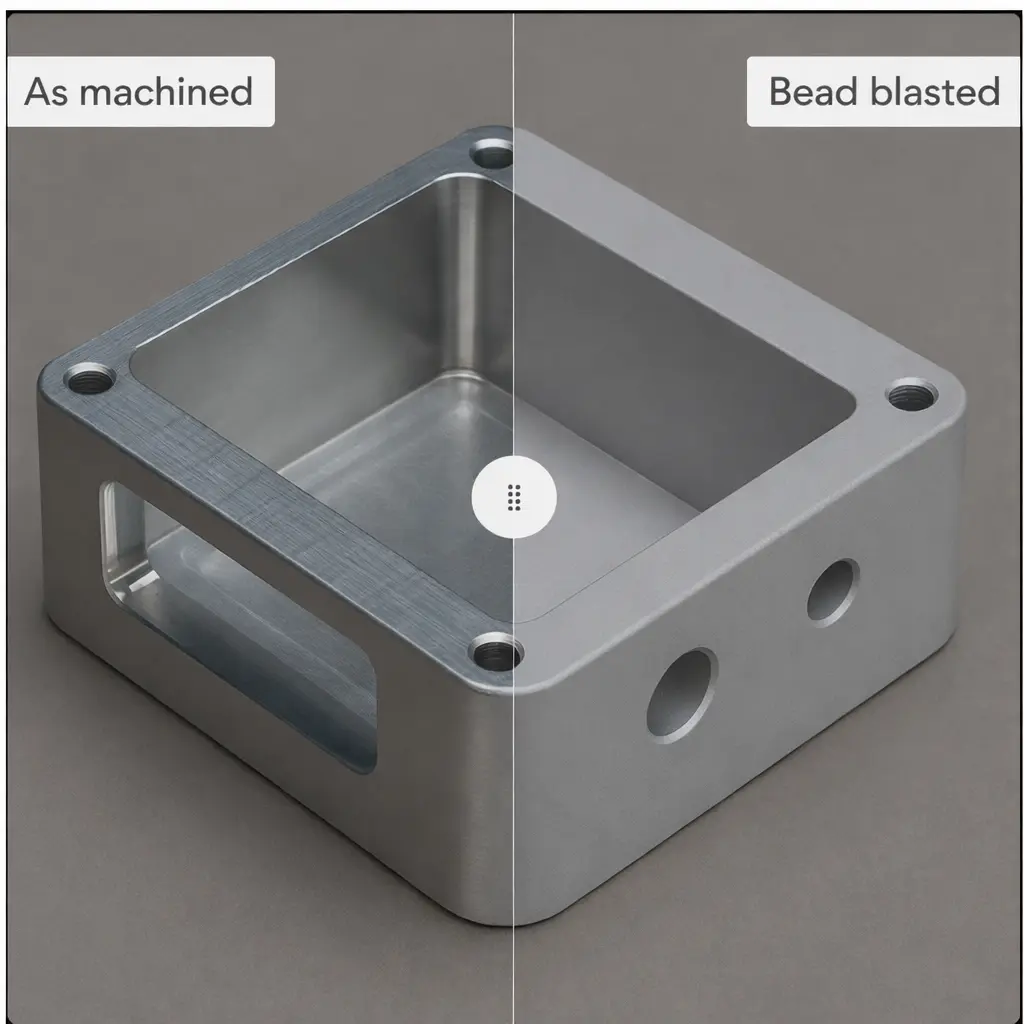

Whether you require a natural anodized look, a colored finish, or a pre-anodizing surface treatment such as bead blasting, hardcoat, or brushing, our team guarantees a consistent, professional finish on all exposed surfaces.

Anodizing is suitable for enclosures, precision parts, and assemblies that require a balance between durability and aesthetics without adding thickness or compromising strict tolerances.

Anodizing – Specification

Option | Category | Purpose | Visual Appearance | Best For |

Standard Anodizing | Primary Finish | Protective oxide layer for durability + cosmetic uniformity | Smooth satin surface in natural/black/selected colors | Enclosures, visible surfaces, general-use parts |

Bead Blasting (Pre-Treatment) | Surface Prep | Minimizes machining marks, smooths surface before anodizing | Matte, even texture | Parts needing a clean and uniform base before anodizing |

Brushed Finish (Pre-Treatment) | Surface Prep | Adds directional grain for a premium brushed look | Satin finish with visible brushed lines | Front panels, control fascias, premium enclosure surfaces |

Hardcoat Anodizing | Enhanced Finish | Thick, dense oxide layer for heavy wear & high durability | Darker, tougher surface | Industrial parts, outdoor exposure, and abrasion-prone areas |

Metal Anodized Part

Design Considerations for Aluminum Anodizing

- Anodizing requires the part to be suspended using a jig or rack.

This creates small contact marks where anodizing cannot occur. - If certain areas cannot have jig marks, include a technical drawing clearly marking those surfaces so our team can plan the holding points.

- Anodizing produces a non-conductive oxide layer.

If any area of the part must remain conductive, please indicate it for masking. - Masking is not applied by default, since standard anodizing adds only a thin layer that does not affect most tolerances.

- If your part has threads, tight-fit zones, grounding points, or precision mating areas, specify whether these surfaces should be masked or anodized.

- Hardcoat anodizing creates a thicker, more durable oxide layer that can affect precision fits.

For such cases, we typically mask threads and critical surfaces unless you request otherwise.

Anodizing Process

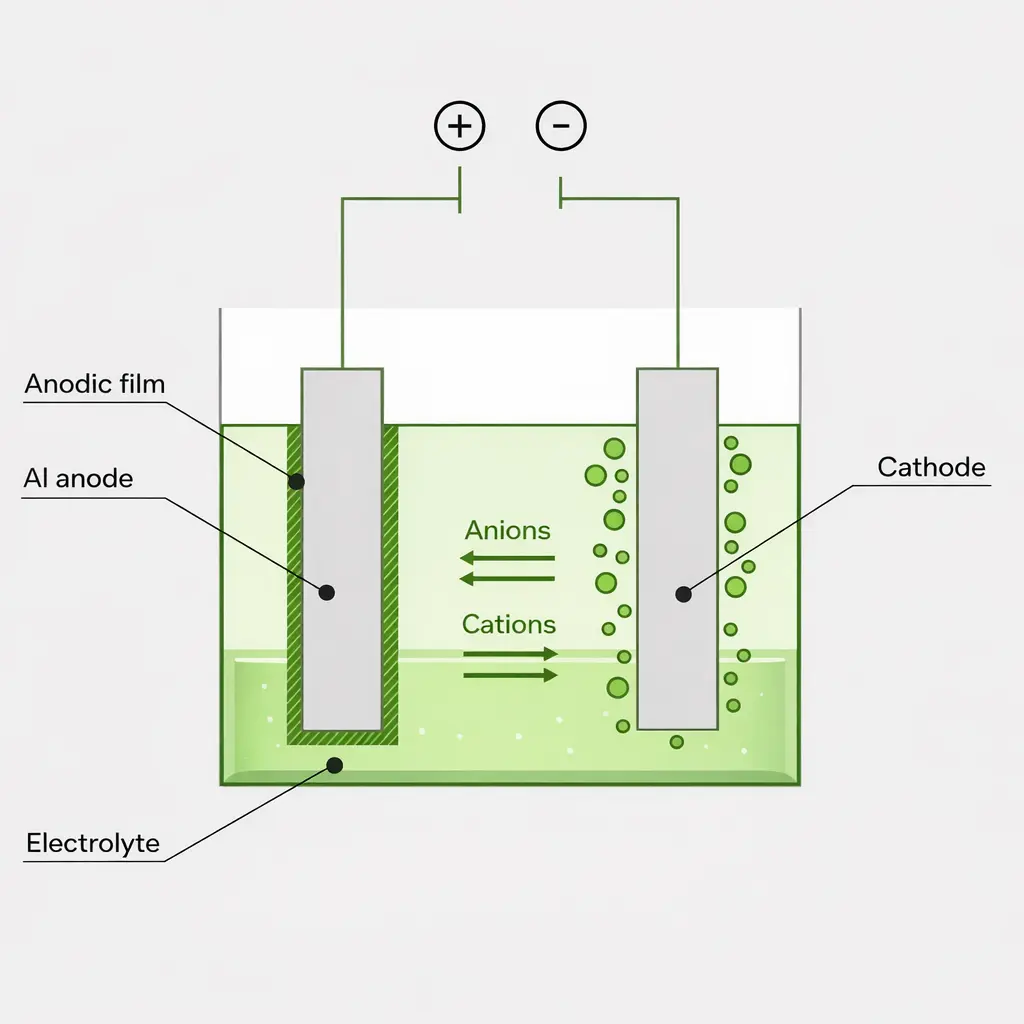

Anodizing is an electrochemical process that reinforces aluminum components, enhances corrosion resistance, and provides a neat, consistent cosmetic finish.

Here’s How We Perform Anodizing at Mech Power:

1. Part mounting

The component is firmly affixed to a rack, allowing electrical current to flow through it during the procedure.

2. Electrolyte setup

The part is placed in a carefully monitored acidic electrolyte solution to establish the optimal conditions for oxide formation.

3. Application of current

An electrical current is introduced, prompting the aluminum surface to react and generate a uniform oxide layer.

4. Formation of oxide layer

Controlled oxidation leads to the formation of a porous aluminum oxide surface, thereby enhancing durability and improving color absorption.

5. Optional dyeing

For aesthetic purposes, the porous layer can be dyed black or in select shades of black.

6. Sealing process

The pores are sealed to retain the color, improve corrosion resistance, and stabilize the anodized finish.

This method yields a tough, uniform anodized coating with dependable dimensional stability, making it perfect for both functional and aesthetic elements of enclosure parts.

Read more about Anodizing

FAQS

Frequently Asked Questions

No. Anodizing creates a non-conductive surface. Mask areas that require conductivity.

4. What colors are available?

Natural (clear), black, and selected colors depending on alloy and geometry.

5. Will jig marks be visible?

Yes, small marks appear where the part is held, share drawings if certain areas cannot have marks.