Upload CAD file/Submit Inquiry

Upload your design or submit inquiry details.

Proudly Powered by PCB Power group - Igniting Innovation, Driving Excellence!

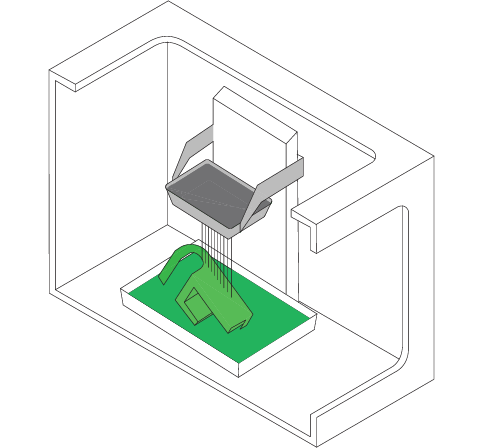

Projection 3D printing, a cutting-edge additive manufacturing method, immerses you in the realm of precision engineering. Here, light meticulously crafts intricate designs, layer by layer, setting the stage for groundbreaking innovation. This technology, known for its remarkable precision and rapid prototyping capabilities, is driving transformative advancements across industries.

Explore our range of versatile Projection Printing Materials printing materials:

Redefining additive manufacturing, it enables a seamless transition from CAD to the manufacturing line in just one day. Exceptional throughput, precision resin molding, and environmental stability set new standards.

Designed for production-grade applications, it ensures a lasting white color and is suitable for medical, consumer goods, and industrial uses, including biocompatibility and smooth finishes.

Versatile and biocompatible, with robust impact strength and endurance. Ideal for high mechanical load-bearing medical parts.

A gray material mirroring injection molding's surface finish. Suited for intricate details, it combines environmental stability with remarkable feature definition.

Engineered for rubber parts, meeting industry standards for reliability in specialized applications.

Durable, flexible, and fatigue-resistant. Perfect for functional prototypes, enclosures, assemblies, and short-run production parts.

Flame-retardant, meeting stringent ratings, and remaining stable at high temperatures. Recommended for consumer, transportation, and aerospace applications.

Balancing impact strength, elongation, and tensile strength for versatile production-grade capability, ideal for load-bearing parts and fixtures.

Customization offerings allow products to be tailored to specific customer preferences or requirements, enhancing personalization and functionality.

Mech Power’s UV printing service enhances your products by offering high-quality, durable prints on various surfaces.

Whether it’s logos, features, product information, or custom designs, our UV printing ensures vibrant colors and sharp details that withstand wear and tear, elevating the overall appearance and branding of your enclosures.

PowerVis is a next gen tool to get quick and hassle-free quotes for your designs. Explore your design in 3D for a detailed, interactive experience.

Upload your design or submit inquiry details.

Configure part specifications and get an immediate quote.

Our engineers will review the design for manufacturability.

We ensure parts are made to meet our high-quality standards.

Confirm payment, and we’ll schedule delivery at your convenience.

Precision parts for automotive and aerospace.

Improved electronic enclosures.

Transform ideas into prototypes and low-volume parts.

Fast Turnaround

No Minimum Order Quantity

Material Variety

Thank you for your interest in our 3D Printing (Projection) service! Our team will get back to you shortly to discuss your requirements further.

Continue to websiteShare your contact details, and our dedicated team will be in touch shortly to discuss your requirements further.

Unlike FDM, Projection Printing cures an entire layer of resin simultaneously using a projected light source. This results in faster printing times and highly detailed, smooth prints.

While Projection Printing excels at creating small to medium-sized parts, the build volume is generally limited compared to FDM or SLA. For larger parts, other technologies might be more suitable.

Yes, parts printed with Projection Printing usually require post-curing under UV light to achieve optimal strength and stability. Additionally, supports need to be removed, and surfaces may require minor finishing.

Projection Printing is cost-effective for projects requiring high precision and intricate details. However, the cost can vary based on material choice, part complexity, and post-processing needs.