Resin 3D Printing is one of the printing methods that allows printing by exposing the images to photosensitive paper. This technique is most common in photography and, lately, in optical lithography, and is a significant process in semiconductor production. The prime advantage of DLP 3D Printing is that it facilitates ratio enlargement or reduction of the images. Hence, it allows more flexibility in print sizes than other methods, such as contact printing.

How Resin 3D Printing Works?

In Resin 3D Printing, the negative is placed between a suitable light source and the lens arrangement. Light is transmitted through the negative, and the lens system projects this light onto photosensitive paper. The size of the projected image can be controlled by altering the distance between the lens and the paper in order to enlarge or reduce it as desired.

Advantages of Resin 3D Printing

The benefits of the Resin 3D Printing are as follows:

- Versatility: Resin 3D Printing offers altering images not only for artistic purposes but also for practical uses, making it highly efficient in handling a lot of photographic works.

- Cropping: A frequently employed technique that includes focusing on certain sections of a negative and enlarging it while cutting out unwanted protrusions in other sections of that photograph.

- Control of Detail: During projection, for instance, dodging and burning techniques can be used, thereby extending the artistic freedom of the print done at the end.

- Conducive to Adjustment: Adjustments in focus and exposure can be done within the course of the printing process, which gives allowance for the photographers to attain the desired image without starting afresh.

Relationship Between Resin 3D Printing and 3D Printing

Both Resin 3D Printing and 3D printing are based on similar principles, more so in using light to form images or objects. Projection printing is generally thought to be a technique of photographic processes. However, in recent years, such techniques have gained much prominence in the area of 3D printing, particularly in processes such as Resin 3D Printing and stereolithography.

Key Similarities Between Resin 3D Printing and Other 3D Printing Techniques

Resin 3D Printing, also known as Figure 4 or Projection Printing, is a specific type of 3D printing that shares several similarities with other 3D printing techniques. Here's how they are related:

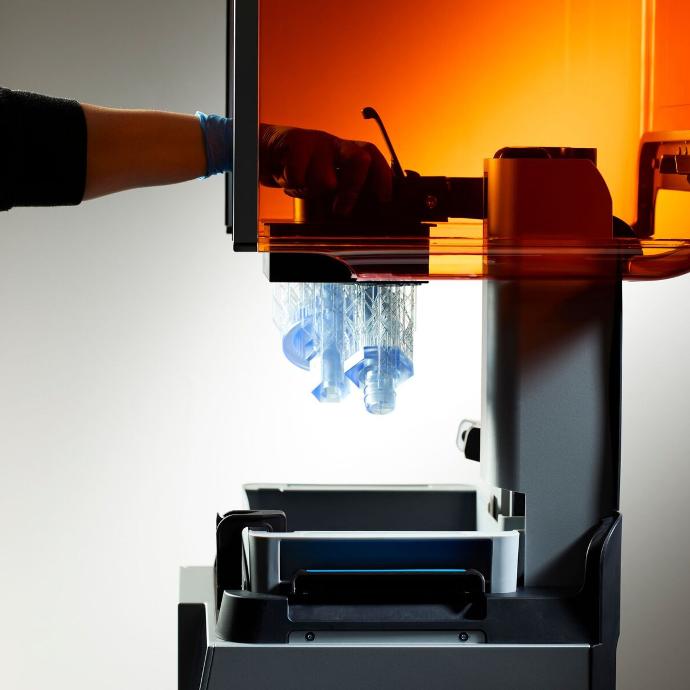

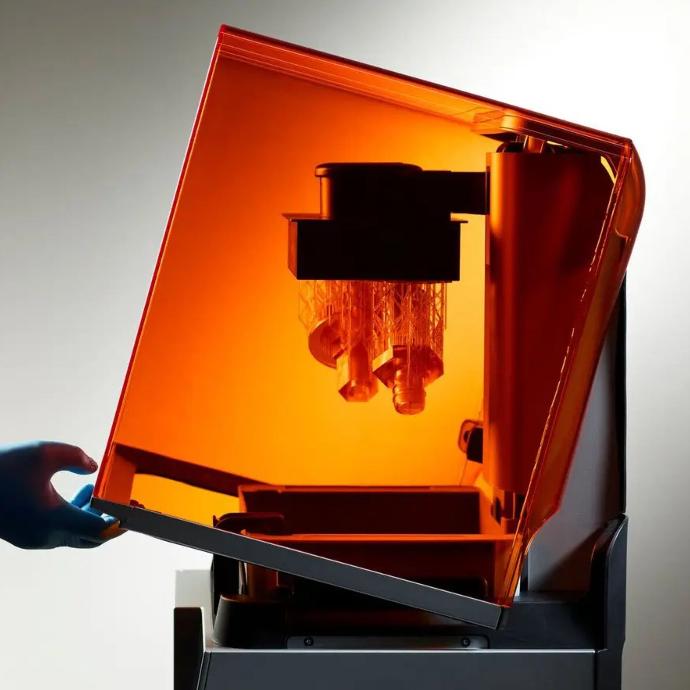

1. Light-Based Technology:Resin 3D Printing and certain 3D printing methods, like SLA (Stereolithography), use light to cure photosensitive resin. In resin 3d printing, a digital projector cures resin layer by layer, while other methods may use lasers or UV light to solidify the material.

2. Layer-by-Layer Construction:Like all 3D printing methods, Resin 3D Printing builds objects layer by layer. This additive manufacturing process allows for the creation of intricate designs, ensuring precision and complexity, which is a hallmark of both Resin 3D Printing and other 3D printing techniques.

3. Customizable Output:In Resin 3D Printing, digital images can be scaled or adjusted for size before printing. Similarly, in other 3D printing techniques, digital models can be resized and customized to fit specific project requirements, whether for prototyping or final production.

Despite being a specific type of 3D printing, resin 3d printing shares these foundational principles with other techniques, making it versatile and highly useful for precision applications.

Conclusion

Resin 3D Printing, also known as DLP (Digital Light Processing), is an advanced 3D printing technology that uses light to cure liquid resin layer by layer, resulting in high-precision, detailed parts. The process is fast, accurate, and ideal for creating complex designs in various industries such as automotive, medical, and electronics. By using a digital projector to solidify resin, this technology offers exceptional speed and resolution, making it a go-to solution for projects that require both precision and durability. As a cutting-edge additive manufacturing method, Resin 3D Printing is transforming the way products are designed and produced.

At Mech Power, we offer Resin 3D Printing services to meet your custom manufacturing needs. Whether you’re creating prototypes or producing final products, our technology provides accuracy and efficiency. Some common applications include creating functional prototypes for electronic enclosures, medical devices, or even small, intricate automotive parts.

To learn more about our Resin 3D Printing services or to place an inquiry, visit our website or contact us at (+91) 98984 12126 or email us at [email protected]. We are here to assist you every step of the way!