If you make panels, plates, or branded sheet metal parts, you have likely asked the same question: how do we get sharp, durable graphics without slowing production? UV printing on a metal surface answers that with quick curing, clean detail, and predictable results. Below is a guide you can share with engineering, procurement, and quality teams.

What Is UV Printing?

UV printing uses LED lamps to cure ink the moment it lands. The ink sets hard in seconds, so smudging drops, handling is easier, and throughput improves. On metal, adhesion relies on good prep, the right primer, and calibrated lamp power. Get those three right, and the print stands up to day-to-day use.

Benefits Of UV Printing

- Instant curing for faster throughput and short production cycles

- Fine detail for serials, QR codes, and micro text

- Low heat load ideal for thin metal sheets and coated surfaces

- Consistent colour accuracy for branding, panels, and repeat batches

- Cleaner workflow with lower VOC output and reduced post-processing

UV Printing at Mech Power

Mech Power Provides UV printing for end plates, control fascias, rating labels, rack fronts and other enclosure parts. We support full colour matching and clean, production-ready prints. Our Pre-press checks cover panel sizing, datum points, bleed, and knockouts, so the artwork moves to sign-off smoothly and the final part matches your build expectations.

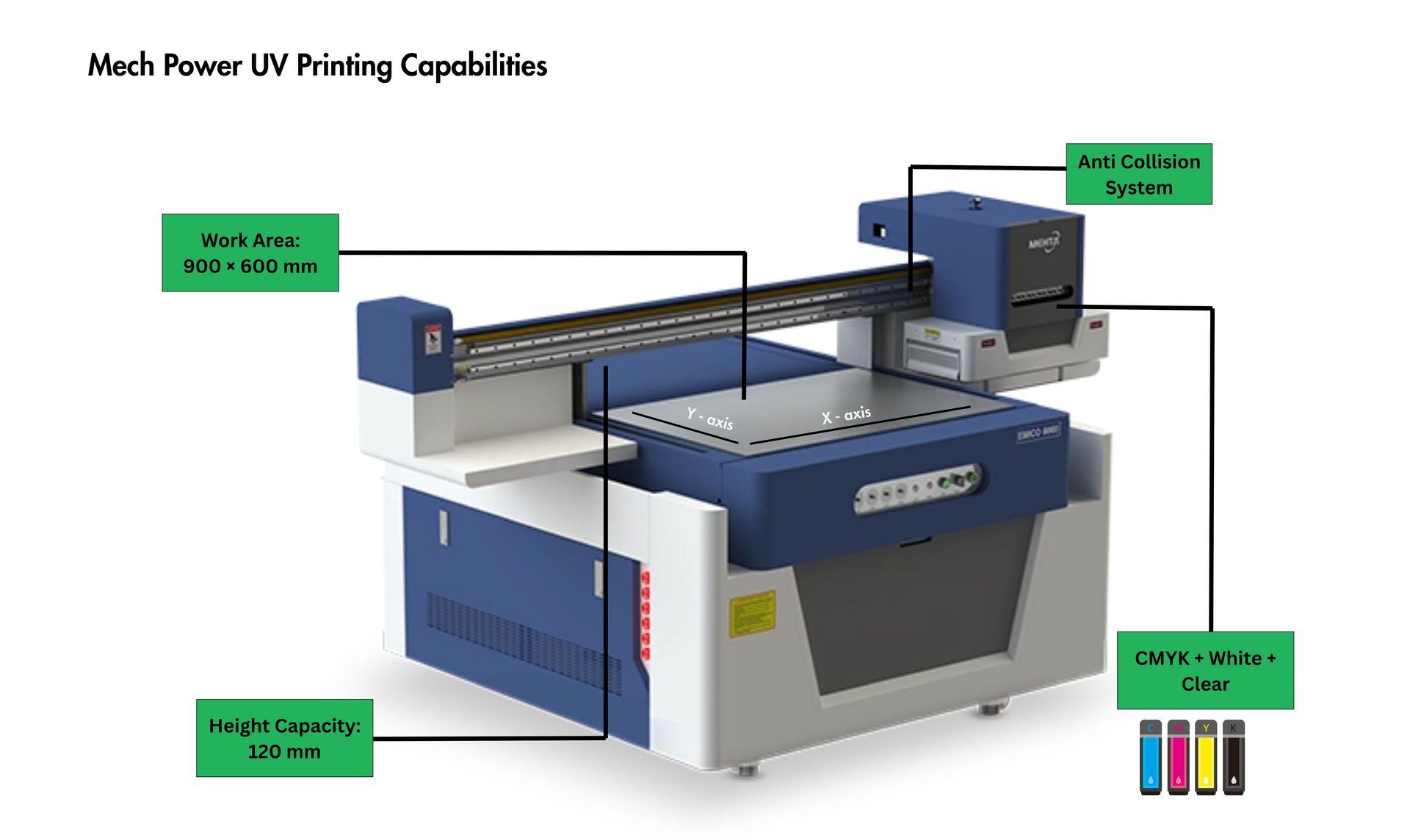

Mech Power UV Printing Capabilities

By our Flatbed Printer, we deliver print quality that is built for industrial environments and enclosure-grade applications:

- Work Area: 900 × 600 mm

Suitable for most enclosure fronts, lids, trays, and nameplates. - Height Capacity: Up to 120 mm clearance

(No material thickness restriction within this height window) - Ink System: CMYK + White + Clear

Layered for opacity, contrast, and textured finishes. - Curing System: Dual UV LED Lamps. Instant curing with low heat impact on coated or thin metal sheets.

- Print Resolution: Up to 600 dpi. Multi-pass mode for photo-grade logos and fine text.

- Material Compatibility: Primers tuned for aluminium, stainless steel, coated steels, brass and copper.

This setup ensures:

- Sharp, abrasion-resistant prints

- Consistent colour performance across batches

- Reliable adhesion on metal surfaces

- Faster turnarounds with minimal handling marks

Step-By-Step Metal UV-Printing Process

- Surface Prep

Degrease, light abrade if needed, clean and dry. Handle with gloves to avoid oils. - Primer

Apply a thin, even coat suited to the alloy or paint system. Flash off fully. - Fixture And Registration

Use jigs for repeatable placement. Align to datum holes or edges. - Print Passes

Lay white underlay where required, then CMYK, then optional clear. - Cure And Checks

Instant LED cure. Run tape tests, barcode scans, and colour checks. - Post-Process

Optional protective lacquer, deburr edges, final inspection, and pack.

Best Metals For UV Printing

- Aluminium raw, brushed, or anodized with the right primer

- Stainless Steel grades 304 and 316, primed for grip

- Coated Steels powder-coated or painted control boxes

- Brass/Copper printable with careful prep and oxidation control

Applications Of Metal UV Printing

Compliance plates, front panels, machine fascias, asset tags, architectural signage, kiosk fronts, rack ears, and short-run promotional items. Use it when you need crisp branding or scannable codes without long drying steps.

Screen Printing On Metal Vs UV Printing On Metal

Screen printing and UV printing are both widely used for marking metal parts, but they serve different production needs. Screen printing excels in large volumes, while UV printing offers speed, precision, and flexibility for short and medium runs. Understanding the difference helps engineering and procurement teams choose the right method for their part, timeline, and finish expectations.

Conclusion: How Mech Power Can Help

Our UV printing process is built around reliability. From artwork checks to primers and lamp profiles, every step is engineered to ensure your panels and metal parts print cleanly, cure instantly, and pass functional tests without rework.

Whether it’s a single prototype or planned batches, our team aligns with your approvals, timelines, and quality expectations. For enclosure fronts, labels, and metal parts that need sharp detail and durable branding, UV printing gives you the right balance of speed, consistency, and long-term performance.

If you’re looking for clear results, Mech Power is ready to support your next build. Contact us now!

FAQS

Frequently Asked Questions

Yes. With the correct primer and cure, prints handle light oils and alcohol wipes. For harsher cleaners, Mech Power can add a clear protective coat.

Within certain height constraints, mild curves and assembled units are possible. Jigs make sure that things are in the right location. During sampling, complex forms are examined.

Devices are verified against Delta E targets and given a profile. Mech Power provides proof on the substrate, so approvals are based on genuine manufacturing.

Logos and panels should be in CDR, Vector AI, PDF, or EPS format. PNG or TIFF photos with a lot of detail. Include sizes, hole centres, and any areas where you can't go.

Aluminium and coated steels are the most predictable. Stainless steel works well with the right primer. Brass and copper need careful prep to limit oxidation.