Every design team has faced it: the perfect circuit, the ideal user interface, yet the enclosure does not cooperate. Ports sit a millimeter too high, vents clash with airflow, or the client insists on bold branding. Off-the-shelf enclosures rarely meet all functional and aesthetic requirements. That’s where Mech Power’s end-to-end enclosure customization comes in.

Mech Power’s Design-First Approach

Mech Power begins every build by understanding the requirements. For every custom enclosure design, engineers review board outlines, connector maps, thermal limits, and mounting points. Drafters build 3-D models while production staff flag manufacturability early. The result is an enclosure engineered for function, optimized for cost and appearance.

Take port cut-outs. Whether it’s tightly staggered RJ-45 lanes or one high-current Anderson plug, Laser or CNC machining delivers precise cutouts in a single pass. This accuracy protects component leads and keeps assembly time consistent, eliminating the need for manual adjustments during assembly.

Functional Customization Options

Your design drives the build. At Mech Power, customization is not an add-on — it’s part of how we engineer every enclosure. We translate your board layouts, component maps, and usage conditions into real features that make integration seamless.

- Precision Cutouts → Our CNC machining and laser cutting deliver clean, accurate port openings for connectors, switches, and displays. No manual rework, no misalignments.

- Ventilation Patterns → From simple slots to engineered airflow arrays, we design openings that manage heat efficiently without compromising structural strength.

- Surface Finishes → Options such as powder coating and anodizing enhance durability, provide corrosion resistance, and offer a professional appearance that aligns with your brand.

- UV Printing → Permanent and high-contrast printing for logos, instructions, safety marks, or functional indicators — ensuring your product is identifiable and user-friendly.

- Mounting & Hardware Provisions → Threaded inserts, standoffs, and mounting brackets can be added during fabrication, saving time during assembly and enhancing reliability in the field.

- Size & Form Adjustments → Whether compact or full rack systems, enclosures are scaled to fit your components while meeting environmental and ergonomic needs.

Each enclosure is engineered to align with your equipment layout, environmental demands, and branding requirements. By combining structural integrity with smart customization, Mech Power ensures that your enclosures perform reliably in the field while reinforcing your product identity.

Material & Structural Choices

The choice of metal can enable or cripple enclosure performance. At Mech Power, we work with mild steel, stainless steel, and several extruded aluminum profiles. Need lightweight EMI shielding for airborne sensors? We’ve got it. Require marine-grade corrosion resistance? We deliver.

Customers often worry about delays in lead times when considering custom electronics enclosures. At Mech Power, we minimize this risk by keeping Sheet Metal Fabrication, CNC Machining, and finishing processes in-house. With fewer external dependencies, timelines remain predictable and delivery stays on schedule.

Where Metal Enclosures Fit Best

Metal enclosures are not one-size-fits-all — their value lies in adapting to the environment where they will perform. Our engineered enclosures are trusted across industries where reliability, protection, and precision matter most.

- Industrial Automation & Control

Protects PLCs, drives, and monitoring units from dust, vibratio,n and harsh shop-floor conditions. - Aerospace & Defense

Lightweight yet rugged enclosures ensure EMI shielding and structural resilience for mission-critical electronics. - Telecommunications & Networking

Custom rack and wall-mount enclosures safeguard switches, routers, and power systems while supporting heat dissipation and cable management. - Energy & Power Systems

From solar inverters to backup power equipment, enclosures are built for outdoor performance with corrosion resistance and weather sealing. - Medical & Laboratory Equipment

Clean, branded enclosures with UV-printed indicators provide both precision protection and professional aesthetics for sensitive devices.

By aligning material choice, structural design, and finishing with the needs of each industry, we make sure that every custom enclosure is more than a box; it becomes part of the system’s long-term reliability.

Thermal and Environmental Refinement

Electronics often face challenges from heat and environmental factors. We address these through smart enclosure design, with proper ventilation, durable sealing, and resilient material choices. Our metal enclosures are engineered to withstand dust, moisture, and outdoor conditions, ensuring reliable protection and long service life.

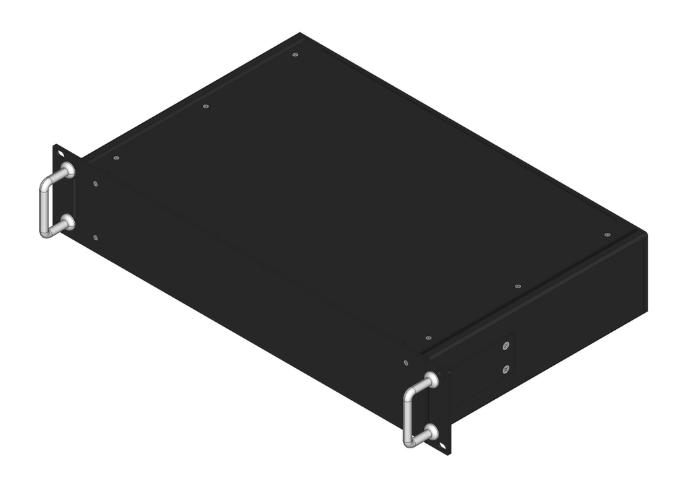

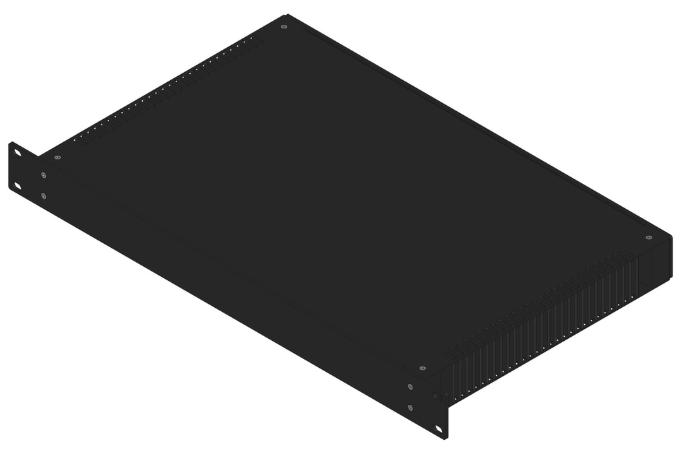

Mech Power Standard Enclosures

At Mech Power, we offer a wide range of standard metal enclosures engineered for performance and designed to integrate seamlessly into your builds. From desktop enclosures and wall-mount enclosures to 19” rack mount enclosures, every product is built for durability and precision.

Along with our standard enclosures, our customization capabilities include precision cutouts, ventilation, powder coating, anodizing, and UV printing to ensure each enclosure is tailored to your exact needs.

End-to-End Process at Mech Power

From specification and design to prototyping, compliance, and serial production — every step flows through one accountable project lead. No time wasted mediating between drafter, machinist, and coater. Clients receive revision-controlled drawings, first-article reports, and a delivery schedule that holds for every build.

Mech Power’s clear communication keeps the team aligned and informed—eliminating the need for constant follow-ups on project requirements

Firms seeking a customized aluminum enclosure manufacturer often juggle several vendors. Mech Power simplifies the chain, resulting in tighter tolerances, faster product release, and simpler warranty claims.

Ready to build the right fit? Get in touch with our team to discuss your next custom requirement.