Annual Update – FY 2024–25

Building Foundations, Enabling Growth

As we wrap up our first full financial year, we’re pleased to share a brief look at what we built, delivered, and learned. This update is part of our ongoing effort to keep our customers, partners, and stakeholders informed and aligned with our journey.

FY 2024–25: Year in Review

This year, our priority was to build a strong foundation and start delivering on our promise of reliable, flexible, and high-quality manufacturing. Here's what we accomplished:

Facility & Infrastructure Set Up

Expanded Capabilities with New Machinery

We added several machines across key manufacturing technologies:

1) FDM and DLP 3D Printing

2) CNC Punching and CNC Press Brake

3) Laser Cutting, Fastener Insertion, and Laser Welding

These additions expanded our ability to handle diverse production needs.

eCommerce Platform Now Live

We launched our online platform, making it easy for customers to explore and order from our standard range of enclosures—including Italtronic products—and access our full suite of services, such as enclosure design, sheet metal fabrication, 3D printing, injection molding, and CNC machining.

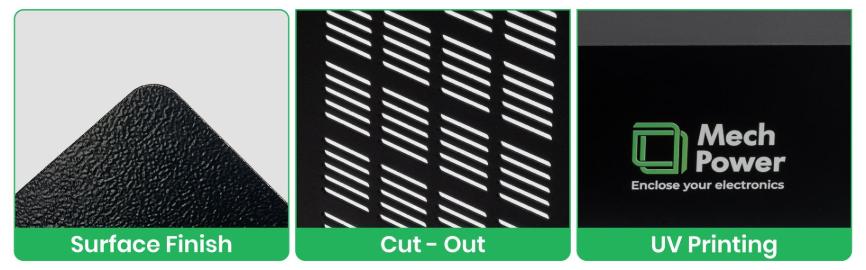

Customization Made Easy

We introduced options for surface finishes, cut-outs, and UV printing, helping customers personalize their enclosures to exact specifications.

Instant Quote Tool for 3D Printing

Our online quote tool now allows customers to upload their designs and receive instant pricing for 3D printed parts—speeding up prototyping and development.

No Minimum Order Quantity (MOQ)

To support innovation and low-volume production, we removed MOQ restrictions across our services.

Active Industry Participation

We participated in over eight exhibitions, including Automation Expo and Electronica India—showcasing our capabilities and learning from industry leaders and peers.

Product Development Milestones

We developed over 450 new enclosures that we offer as products on our platform

Welcoming Italtronic

During the Italtronis team’s visit to our facility, we inaugurated our new laser cutting machine and demonstrated our growing fabrication capabilities.

Who We Served

1) Served 180+ customers across industries

2) Designed and manufactured 250+ custom sheet metal parts for a variety of applications

Challenges We Tackled

Balancing Customization with Delivery Timelines

Many projects required customized designs with quick turnarounds. We addressed this by refining our workflows, improving scheduling, and streamlining engineering reviews.

Precision Demands

High-detail and tight-tolerance parts pushed us to improve accuracy. We met this challenge by investing in better tooling, enforcing process control, and strengthening coordination between our design and production teams.

Looking Ahead: FY 2025–26

New Product Launches

We’re preparing to launch Profile Enclosures and expand our enclosure product range to offer more variety and flexibility.

Faster Lead Times

We’re working to shorten delivery times through smarter scheduling and better resource planning.

Expanding Globally

We’re setting our sights on international markets and building the capabilities to serve a wider customer base across borders and promote Make in India.

Industry-Aligned Services

We aim to tailor our enclosure solutions for sectors like Electric Vehicles (EV), Automotive, Aerospace, Medical Devices, and Industrial Automation—where precision and customization are critical.

Closing Note

FY 2024–25 was a foundational year—about building, delivering, and learning. We’re grateful for the trust our customers and partners placed in us.

As we grow, we remain committed to being a dependable manufacturing partner—one that empowers innovation with speed, flexibility, and quality.

We look forward to working together in the year ahead.

Chief Operating Officer