Bead blasting allows us to prepare your metal parts and enclosures with a clean, flat surface that looks good and functions well.

It uses high-pressure glass beads to eliminate machining marks, smooth small flaws, and provide a uniform matte or satin finish on the part.

Whether you need a functional finish for easier handling and assembly, as well as a visual finish for a cleaner look, our team can support both.

Bead Blasting Specifications

Applicable Materials | Media Used | Visual Appearance |

Aluminum, Mild Steel, Stainless Steel, Galvanized Iron | Glass beads (industry-standard grit range: #100–#120) | The texture is smooth, even matte. Machining marks are minimized for functional finishes and completely erased from major visible surfaces. |

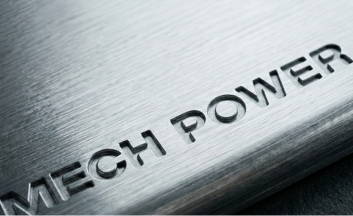

Sample Beadblasted Part

How does a bead blasting surface finish work?

Bead blasting enhances the surface of metal parts by shooting fine glass beads at a regulated pressure. The impact eliminates machining marks, smooths out sharp transitions, and results in a uniform matte finish without changing the dimensions of the part.

Coarser beads yield a more textured finish, whereas finer beads provide a gentler satin look. This technique is effective on Aluminum, Mild Steel, Stainless Steel, and GI parts, making it a dependable option for deburring and prepping parts for painting, powder coating, or anodizing.

At Mech Power, bead blasting is utilized to enhance both the functional grip and aesthetic appearance of enclosures and manufactured parts.

Bead blasting process

Here’s how we carry out bead blasting for your enclosure and metal parts:

- Parts are first fabricated through sheet metal processing

- After inspection, parts are moved to our bead blasting station

- Surfaces are blasted using controlled glass bead media (industry-standard grit #100–#120) to achieve a uniform matte finish

This process ensures consistent texture, reduced machining marks, and a finish that’s ready for powder coating, painting, or cosmetic use.

Hardcoat Anodizing: Surface Finish Overview

A hardcoat finish fortifies and protects your metal components by forming a solid, wear-resistant surface layer.

It promotes hardness, durability, and corrosion resistance, preparing your parts for tough industrial applications and long operating life.

This finish is perfect for aluminum objects that require a more durable surface without affecting dimensions. It also helps to ensure constant performance in applications where the parts are subjected to repetitive friction, abrasion, or weather exposure.

Whether you require high-strength enclosure protection or a long-lasting decorative finish, our team guarantees uniform coating thickness and consistent functional performance.

Hardcoat Finish Specifications

Applicable Materials | Media / Method | Visual Appearance |

Aluminum | Hardcoat anodizing (controlled electrolytic oxidation) | Dense, dark grey to charcoal coating with a satin, durable surface. |

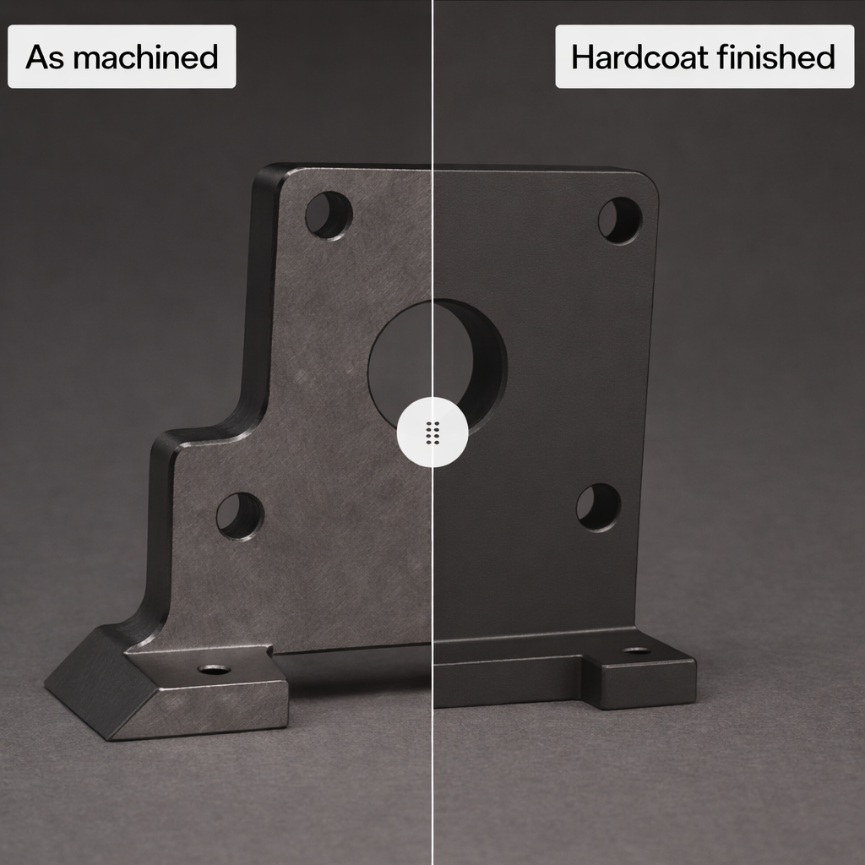

Sample Hardcoat Part

How does a hardcoat surface finish work?

The hardcoat finishing process enhances aluminum parts by forming a thick, dense oxide layer via a controlled Type III anodizing method. This electrochemical reaction transforms the aluminum's outer surface into a robust protective coating, greatly improving wear resistance and preventing corrosion.

In contrast to standard anodizing, hardcoat produces a deeper and more resilient layer capable of enduring abrasion, continuous friction, and demanding environmental conditions. The finish usually appears in shades ranging from dark grey to charcoal while preserving dimensional stability with minimal surface expansion.

At Mech Power, hardcoat finishing is preferred for enclosure components and aluminum parts that demand long-lasting durability, consistent performance, and the ability to handle significant operational loads.

Our Hardcoat process

Here's how we apply hardcoat finishing to your enclosure and aluminum parts:

- Parts are first manufactured using sheet metal processing or CNC machining.

- Surfaces are cleaned and prepared for optimum adherence and homogeneous coating.

- Parts go through regulated hardcoat anodizing to create a thick, wear-resistant oxide coating.

This method produces a highly robust, corrosion-resistant surface while retaining dimensional accuracy ideal for aluminum products that require long-term performance in harsh environments.

Brushed Finish: Surface Texture Overview

A brush finish gives your metal parts and enclosures a clean, directional grain using controlled abrasive belts.

It smooths the surface, removes machining lines, and creates a consistent brushed texture that enhances the look and feel of the metal part and enclosure.

This finish is ideal when you want a more refined, satin appearance, especially for parts that remain visible in the final product. It improves visual quality while maintaining dimensional accuracy, making it suitable for both standalone enclosures and custom-built assemblies.

Whether you need a subtle aesthetic upgrade or a premium brushed look for your project, our team ensures a uniform, professional finish across every surface.

Brush Finish Specifications

Applicable Materials | Media / Method | Visual Appearance |

Aluminum, Stainless Steel, Mild Steel | Abrasive belts / Scotch-Brite wheels (typically 80–180 grit belt) | Directional grain, satin appearance, visible brushed lines |

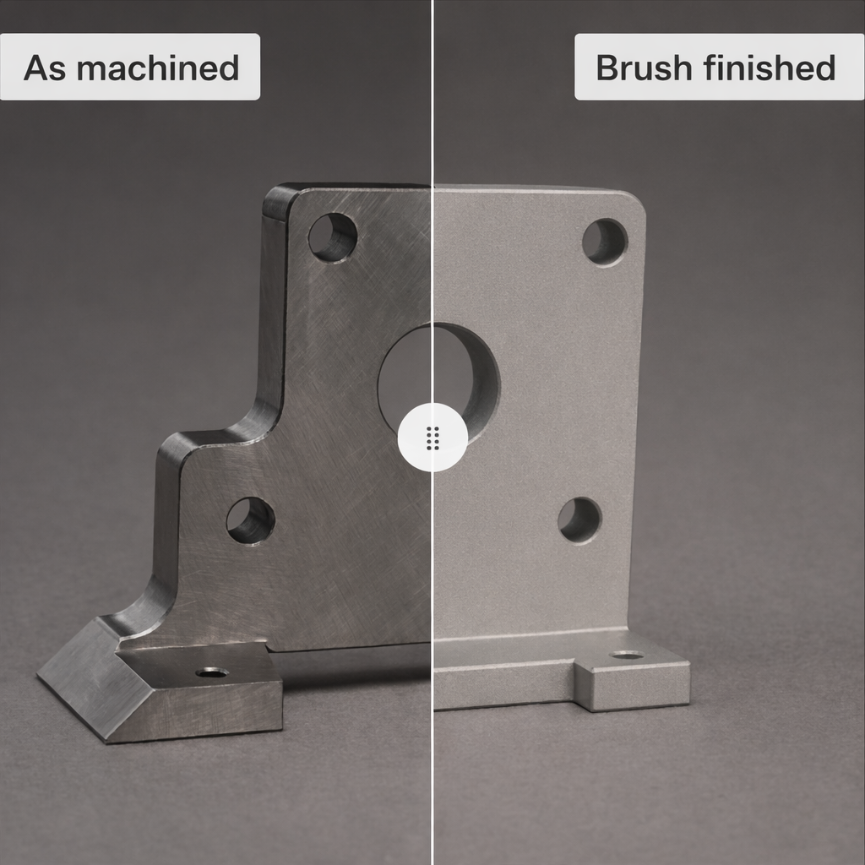

Sample Brushed Part

How does a brushed surface finish work?

A brushed surface finish is accomplished by applying abrasive belts or Scotch-Brite wheels to the component in a uniform direction. This controlled abrasion eliminates machining marks, smooths out surface inconsistencies, and creates a tidy linear grain that improves the overall appearance and feel of the component.

Using coarser belts results in a more distinct grain, whereas finer abrasives give a more polished satin finish. This type of finish is perfect for parts that will be visible in the finished product and require a sophisticated and premium look without changing dimensions.

At Mech Power, we utilize brushed finishing to enhance the visual attractiveness of enclosures and fabricated parts while maintaining a consistent grain pattern that aligns with the design intent and the final presentation of the product.

The Mech Power brush finish process

Here’s how we carry out brush finishing for your metal parts, components, and enclosures:

- Parts are first fabricated through sheet metal processing.

- Parts are deburred to remove sharp edges and prepare the surface.

- Abrasive belts or Scotch-Brite wheels are applied in a single, consistent direction to create a uniform brushed grain.

This process delivers a clean, directional satin texture, improves visual appeal, and prepares the part for assembly or additional finishing without affecting dimensional accuracy.

FAQS

Frequently Asked Questions

Bead blasting is a process that uses fine glass beads to smooth the metal surface and remove machining marks.

It produces a clean, uniform matte texture that’s ideal as a base for coating or anodizing.

Choose it when you need a smoother, more consistent surface before painting, powder coating, or anodizing.

Very minimally, bead blasting only removes surface-level imperfections and does not change tolerances.

Yes, bead blasted parts are excellent for powder coating because the texture helps coating adhesion.

A brushed finish creates a linear, satin-like texture using controlled abrasive strokes.

It’s used on visible surfaces of enclosures where a clean, premium, directional grain is required.

It reduces minor defects, but deep scratches may remain visible depending on grain depth.

Yes, brushed metal is often anodized to achieve a premium aesthetic with added protection.

No, brushing only affects the surface top layer and does not impact fit or tolerances.

A thick, durable anodized layer on aluminum.

When the part needs high wear and corrosion resistance.

Very minimally; growth is controlled.

Dark grey to charcoal with a smooth, dense surface.

Yes, ideal for tough, long-life aluminum enclosures.