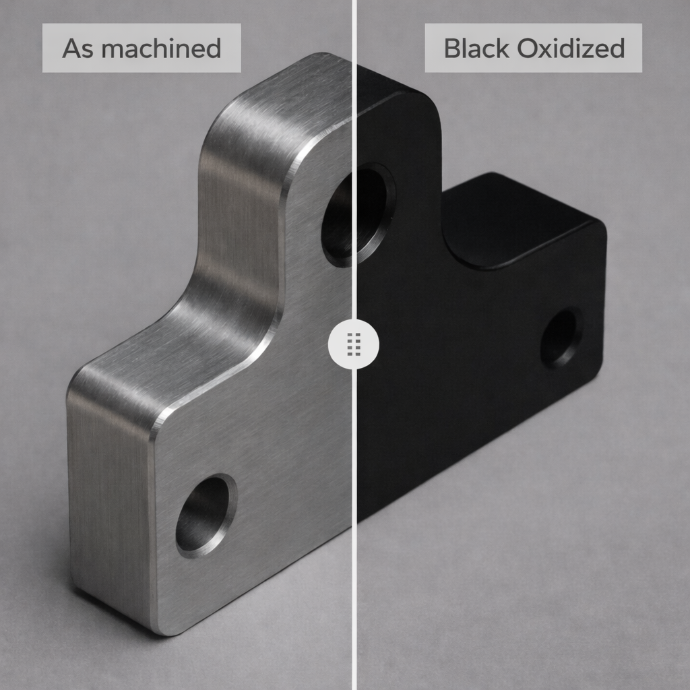

Black oxide imparts a uniform matte black coating to steel and stainless-steel parts without increasing thickness, making it ideal for components with tight tolerances.

It enhances surface strength, diminishes reflections, and offers a level of light corrosion resistance through a stable oxide coating.

When treated with oil, the finish gains durability, making it perfect for enclosures, brackets, and precision-machined parts that require a clean, consistent look along with extra protection.

Black Oxide Specification

Surface preparation | Colors | Applicable materials | Thickness | Visual appearance |

As machined (Ra 3.2 µm / Ra 126 µin) | Black oxide finish | Mild Steel, Stainless Steel, Galvanized Iron (Aluminum not compatible with black oxide) | 0–30 µm | Smooth matte black |

Sample of Black Oxidized Part

Design considerations for black oxide

Masking:

Black oxide adds almost no measurable thickness to the part. Since it is a conversion coating (not a deposited layer), it does not alter critical dimensions.

Because of this, masking is generally not required unless a specific area must remain completely untreated for electrical or functional reasons.

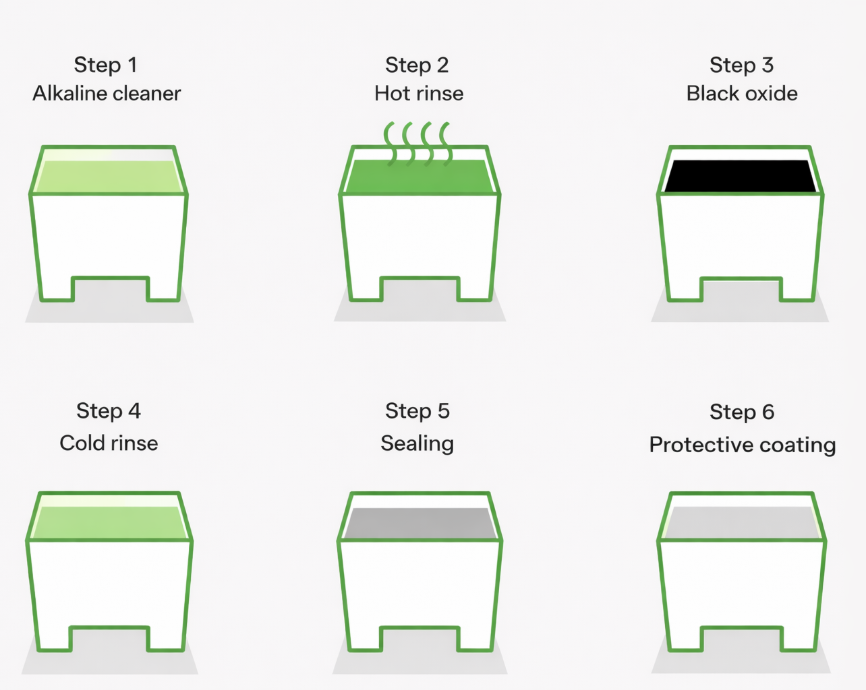

Black Oxide Process

Black oxide is a conversion coating applied to steel and stainless-steel parts to achieve a smooth, uniform black appearance.

It adds almost no measurable thickness and provides mild corrosion resistance, especially when sealed with oil.

At Mech Power, we follow a controlled, step-by-step process to ensure every part gets a consistent, high-quality finish.

Here’s how we apply black oxide at Mech Power:

- 1. Initial fabrication

Parts are first machined, deburred, or cut through our sheet metal or CNC processes to ensure clean, burr-free surfaces. - 2. Alkaline cleaning

Components are cleaned using an alkaline solution to remove oils, fingerprints, and contaminants that can affect coating quality. - 3. Rinse stage

Parts are thoroughly rinsed with water to prepare them for the oxidizing bath. - 4. Black oxide treatment

The parts are immersed in a controlled hot alkaline bath (typically 135–145°C).

Depending on the size and geometry, the immersion time varies between 5 and 40 minutes to achieve a uniform conversion layer. - 5. Final rinse

After oxidation, parts are rinsed again to remove any residual chemicals. - 6. Sealing for protection

The black-oxidized surface is then sealed using oil, wax, or lacquer.

This helps deepen the black finish and enhances corrosion resistance, especially for parts used in industrial or outdoor environments.

Read more about Black Oxidizing

FAQS

Frequently Asked Questions

Black oxide works on mild steel, stainless steel, and galvanized iron.

Aluminum cannot undergo black oxide treatment.

It reduces surface reflectivity, adds mild corrosion protection, and improves the overall appearance with a smooth matte finish.

No. Because it is a conversion coating, the dimensional impact is negligible, making it suitable for tight-tolerance parts.

Only minor imperfections are softened. Deep scratches or tool marks will still be visible under the coating.

Oil fills the porous surface layer, increasing corrosion resistance and enhancing durability, especially for parts used in daily operation.