Chromatizing is a chemical conversion coating applied to aluminium to create a thin, protective yellow chromate layer.

It improves corrosion resistance, maintains electrical conductivity, and provides a stable base for powder coating or paint.

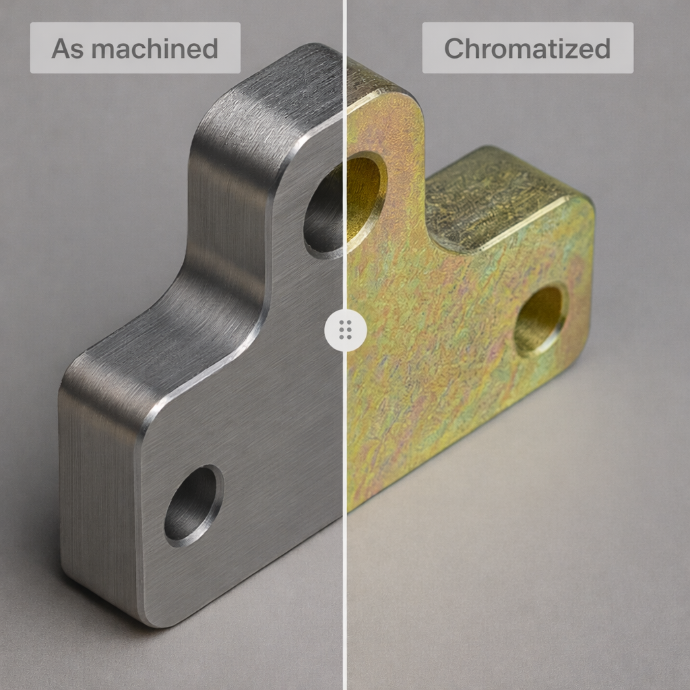

The finish naturally shows a yellow-iridescent tint, which becomes more visible under angled or UV lighting.

Chromatizing – Specification

Surface preparation | Colors | Applicable materials | Thickness | Visual appearance |

As machined (Ra 3.2 μm / Ra 126 μin) | Yellow chromate tint with subtle iridescent/UV-visible colors | Aluminium (All standard grades except 7xxx series) | Negligible, almost no dimensional change | Machining marks remain visible; the yellow chromate layer shows light iridescence under UV or angled light |

Sample of Chromatized Part

Design considerations for chromatizing (yellow chromate):

- Chromatizing creates a fragile conversion layer, so part dimensions and tolerances remain unchanged.

- The coating is suitable only for aluminium alloys; steel or iron parts cannot be chromatized directly.

- Machining marks and surface texture remain visible, as this is a functional, rather than cosmetic, finish.

- The coating preserves electrical conductivity, making it suitable for grounding surfaces.

- Chromatizing works well as a base layer for powder coating or paint due to improved adhesion.

How Chromatizing Works at Mech Power

Chromatizing creates a thin yellow chromate layer on aluminium to improve corrosion resistance and maintain conductivity. The finish exhibits a natural, yellow–iridescent tint.

Process We Follow

- Parts are cleaned and degreased to remove contaminants.

- Cleaned parts are rinsed thoroughly.

- Aluminium parts are dipped in a trivalent chromate bath, where the conversion layer forms.

- Parts are removed once the yellow film develops.

- A final rinse and drying step stabilizes the coating.

FAQS

Frequently Asked Questions

Chromatizing is suitable only for aluminium alloys. Steel or iron parts cannot be coated directly.

No. The conversion layer is extremely thin, so the part retains its original tolerances and dimensions.

Yes. Chromatizing does not hide tool marks or surface texture. The finish remains functional, not cosmetic.

Yes. Chromatizing forms a protective conversion layer that enhances the aluminium’s resistance to corrosion.

The yellow chromate layer naturally reflects light differently, creating subtle iridescent or UV-visible effects.