Choosing a resin is a design decision. It affects how your part behaves during assembly, how it holds up in real use, and how consistent your results stay across batches. The right resin can save rework and improve reliability; the wrong one can crack, warp, or lose clarity when the product reaches the field.

This quick guide walks through the main resin categories, what they do best, and a few design habits that keep results consistent. If you are short on time, skim the “Quick Resin Line-Up” and match your part to the closest use case.

Understanding What Your Part Needs

Start with three questions. What will the part do in the real world? How will it be handled or cleaned? Does the surface need to be clear, painted, or labelled? These answers guide the choice toward strength, stiffness, clarity, temperature resistance, or flexibility. Once the functional needs are clear, resin selection becomes a straightforward engineering decision not trial and error

Quick Resin Line-Up

Standard Resins For Visual Models and Fit Checks

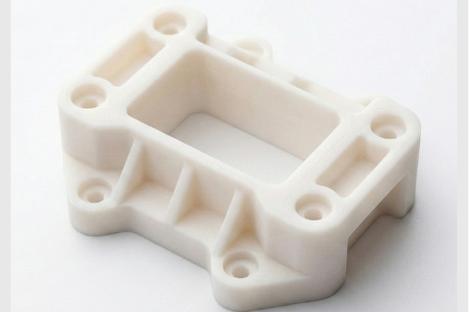

Standard resins are your go-to when you need clean geometry, sharp detail, and quick validation. They are ideal for visual mock-ups, light jigs, covers, or parts that only need to prove form and fit before moving to engineering-grade options

- Rigid White

- Rigid Gray

Tough or ABS For Everyday Strength and Handling

Made for clips, housings, and brackets that see knocks. They offer more bend strength and durability than standard grades and are often used for enclosure components in early functional builds.

- PRO-BLK 10

- Tough 60C White

- Tough Gray 15

Flexible and Elastomeric Resins For Grip, Sealing, and Vibration Control

They are generally used for soft-touch grips, gaskets, vibration-damping elements, and protective covers.

- Flex-BLK 20

Design Habits That Pay Off

- Wall thickness: For most resin builds at Mech Power, use a minimum wall of 1 mm to balance speed, strength, and dimensional stability.

- Holes: Print holes slightly undersized and drill to final size when tolerances matter. This keeps alignment sharp and prevents ovality.

- Orientation: How you orient the part affects both strength and the final look.

Keep critical faces away from supports and align layer lines with the load, especially for snaps, hinges, or thin sections.

- Fillets: Add generous fillets in load paths and at the base of clips or hooks to distribute stress. Sharp internal corners tend to crack under use.

- Design to platform: Maximum build volume: 124 × 70 × 195 mm (W × D × H).

Designing to this space avoids scaling compromises and ensures support structures remain manageable.

- Accuracy you can rely on: Dimensional accuracy ±0.25%, with a minimum deviation of ±0.25 mm helps designers plan for fits, clearances, and mating parts.

Finish, Colour, And Labelling

Resin parts finish well as long as the prep is right. Most materials can be sanded, and painted to achieve a clean, uniform surface. For show parts, step through multiple sanding grits, then topcoat for consistent colour across batches. Paint offers tighter colour control than dyed vats, especially when parts need to match brand guidelines. At Mech Power, we support dry and wet sanding, along with matte or glossy paint finishes, to give prototypes and functional parts a stable, repeatable surface.

For labels, recess a panel to protect decals or emboss text at about 0.4 mm so it stays legible after paint. For parts requiring optical clarity, talk to our team about post-processing options and whether polishing or alternative finishing methods are suitable for your geometry and resin choice.

Chemical, UV, And Cleaning Considerations

Resin parts react differently to everyday environments. Exposure to alcohol, detergents, or solvents can change surface properties or cause swelling over time. UV light may also lead to yellowing or reduced strength, especially in clear and lighter materials. If your part will see regular cleaning, outdoor use or contact with chemicals, tell our team in advance so that they can guide you toward resin grades that maintain stability under those conditions. Store printed parts in cool, shaded areas when possible and follow resin-specific cleaning instructions for consistent long-term performance.

How Mech Power Can Help

Here is the simple journey you can expect with us: get an instant quote, you share your design, we review it with engineering precision and your parts move into printing, finishing, and dispatch without unnecessary delays. The goal is simple clear steps, predictable outcomes and parts that perform exactly the way you expect.

- Engineering-led review, every time: Upload your CAD for a fast price. Our engineers check geometry, tolerances, and resin fit before a single layer is cured.

- Material options built around real-world use: From PRO-BLK 10, Tough and Rigid grades to Flex and clear options, we match resin to strength, impact, heat, clarity, or ESD needs.

- No minimum order quantity: You can print a single prototype, a small functional batch, or repeat runs without commitment. This flexibility helps teams validate their ideas before scaling.

- Consistent print quality: We tune orientation, supports, and post-cure so parts repeat across batches and builds.

We match material to the job before we print. Share your use case, handling routine, and any compliance you need and we will suggest a short trial run. If your team is new to resin, our team can also suggest small CAD refinements like improving snap-fit geometry to help your parts last longer in the field.

Conclusion: A Simple Next Step

Ready to choose with confidence? You can place your order directly. Just visited our instant quote page -> select Resin 3D printing -> upload your CAD, pick your resin material and colour, confirm the specs, and submit. We handle the engineering checks and begin production right away.

Explore our Resin 3D Printing Services to see available materials, finishing options, and build capabilities.